The Future of High-Reliability Electronics

Solderless assembly with inherent thermal management—engineered for defense, aerospace, medical, and automotive applications where failure isn't an option.

Connect With UsWhy Choose

The Occam Group

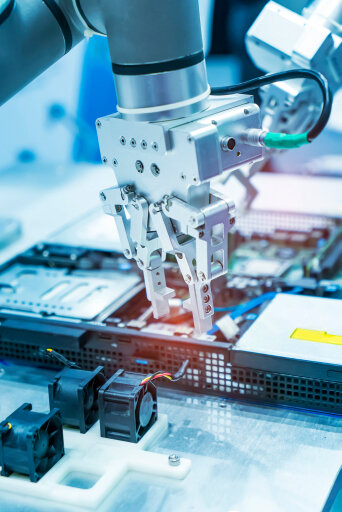

Solderless Assembly Technology

Eliminates solder by bonding components first, removing common failure points.

Superior Reliability

Immune to solder-related failures from shock, vibration, and heat.

Inherent Thermal Management

Thermally conductive substrates naturally dissipate heat for efficient operation.

Reduced Size and Weight

Components sit closer, making assemblies smaller and lighter.

Lower Production Costs

Fewer steps, less material, and no solder rework save money.

Additive Manufacturing Compatibility

Supports rapid prototyping, short runs, and customizable designs.

The Occam Process

The Occam Process is a patented solderless assembly method, a substrate technology that delivers reliable, lower cost, and smaller electronics systems for some of the most demanding applications in the world.

Through our innovative approach, we create direct metallurgical bonds that outperform traditional solder joints in every measurable way—from thermal conductivity to mechanical strength.

Learn More About Our ProcessMarkets We Serve

From defense applications to consumer electronics, the Occam Process delivers reliability where it matters most.

Defense & Aerospace

Mission-critical reliability for the most demanding environments.

Medical Electronics

Life-saving devices that demand zero tolerance for failure.

Automotive

High-performance electronics for next-generation vehicles.

Consumer Electronics

Compact, reliable solutions for everyday devices.

Data Centers

Thermal management for high-density computing.

Semiconductor Packaging

Advanced packaging solutions for next-gen chips.

Inherent Benefits

The Occam Process delivers measurable advantages over traditional electronics manufacturing methods.

EMI/ESD Immunity

Thermal Management

Design Security

Reduced Footprint

Partner With Us

Join the growing number of industry leaders who trust The Occam Group for their mission-critical electronics needs.

Whether you're looking to improve reliability, reduce costs, or solve thermal challenges, our team is ready to help you achieve your goals.

Learn How to Partner With UsResources

Explore our library of technical papers, white papers, and case studies to learn more about the Occam Process and its applications.

- Technical Papers & White Papers

- eBook: "SAFE - Solderless Assembly for Electronics"

- Video Interviews & Presentations